Synthesis, Properties, and Applications of Iron Oxides: Versatility and Challenges

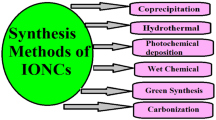

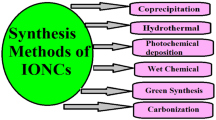

Iron (III) oxide is a compound that appears in at least four different polymorphs: α-Fe2O3, β-Fe2O3, γ-Fe2O3, and ε-Fe2O3. However, Fe 3+ ions are also present in another form of iron oxide: Fe3O4, which is an iron crystal structure with both Fe 2+ and Fe 3+ ions. And in its turn, Fe 2+ ions are also present in the FeO form of iron oxide. Each of these six different structures presents distinctive physical properties and, therefore, diverse applications. The different crystalline forms of iron oxide have found fertile ground in the field of nanotechnology, and therefore, became popular among researchers who have proven a wide variety of biomedicine, electronics, construction, environmental remediation, and energy harvesting applications. In this regard, the main technological challenge is related to control of its physical characteristics such as morphology, size distribution, dispersion, crystallinity, structural defects, porosity, active area, as well as impurities. All of these influence the physical and optical properties of the synthesized material and will determine its field of application. As such, the synthesized material characteristics depend on the synthesis method employed. Thereby, in this chapter, we will cover the main characteristics of iron oxides with a focus on preparation processes, physicochemical properties, and their relationship with their main applications.

This is a preview of subscription content, log in via an institution to check access.

Access this chapter

Subscribe and save

Springer+ Basic

€32.70 /Month

- Get 10 units per month

- Download Article/Chapter or eBook

- 1 Unit = 1 Article or 1 Chapter

- Cancel anytime

Buy Now

Price includes VAT (France)

eBook EUR 128.39 Price includes VAT (France)

Softcover Book EUR 163.51 Price includes VAT (France)

Hardcover Book EUR 232.09 Price includes VAT (France)

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

Synthesis, Characterizations and Applications of Iron Oxide-Based Nanocomposites

Article 08 September 2023

Synthesis, Morphology and Environmental Applications of Iron Oxide-Based Nanoarchitectures

Chapter © 2024

A narrative review of the synthesis, characterization, and applications of iron oxide nanoparticles

Article Open access 10 October 2023

References

- Cornell, R.M., Schwertmann, U.: The Iron Oxides: Structure, Properties, Reactions, Occurrences and Uses. Wiley (2003) Google Scholar

- Schwertmann, U., Cornell, R.M.: Iron Oxides in the Laboratory: Preparation and Characterization, 2nd ed. Wiley-VCH (2008) Google Scholar

- Fernández-Remolar, D.C.: Iron oxides, hydroxides and oxy-hydroxides BT—encyclopedia of astrobiology. In: Gargaud, M., Irvine, W.M., Amils, R., Cleaves, H.J. (Jim), Pinti, D.L., Quintanilla, J.C., Rouan, D., Spohn, T., Tirard, S., Viso, M. (eds.), pp. 1268–1270.. Springer, Berlin, Heidelberg (2015). https://doi.org/10.1007/978-3-662-44185-5_1714

- Li, S.: Structural Design, Characterization, and Property Investigation of Iron Oxide (Nanoparticles with Visible Light Photoactivity), University of Paul Verlaine-Metz and Northeastern University (2009) Google Scholar

- Atkins, P., Overton, T., Rourke, J., Weller, M., Armstrong, F.: Shriver & Atkins’ Inorganic Chemistry, 5th edn. Oxford University Press, USA (2010) Google Scholar

- Shannon, R.D.: Revised effective ionic radii and systematic studies of interatomic distances in halides and chalcogenides. Acta Crystallogr. Sect. A 32(5), 751–767 (1976). https://doi.org/10.1107/S0567739476001551ArticleGoogle Scholar

- Ahmed, M.A., Okasha, N., Nabeel, D.: The formation and characterization of nanocrystalline Mn-ferrite from magnetite. In: Modern Trends in Physics Research, pp. 104–109. WORLD SCIENTIFIC (2013). https://doi.org/10.1142/9789814504898_0015

- Aschauer, U., Hockridge, J.G., Jones, F., Loan, M., Parkinson, G.M., Richmond, W.R.: Morphology control in the synthesis of iron oxide and oxyhydroxide nanoparticles. In: 2006 International Conference on Nanoscience and Nanotechnology, p. 1 (2006). https://doi.org/10.1109/ICONN.2006.340547

- Momma, K., Izumi, F.: VESTA3 for three-dimensional visualization of crystal, volumetric and morphology data. J. Appl. Crystallogr. 44(6), 1272–1276 (2011). https://doi.org/10.1107/S0021889811038970ArticleCASGoogle Scholar

- Campos, E.A., Pinto, D.V.B.S., de Oliveira, J.I.S., Mattos, E.C., Dutra, R.C.L.: Synthesis, characterization and applications of iron oxide nanoparticles—a short review. J. Aerosp. Technol. Manag. 7(3), 267–276 (2015). https://doi.org/10.5028/jatm.v7i3.471

- Carter, C.B., Norton, M.G.: Ceramic Materials: Science and Engineering, vol. 716. Springer (2007) Google Scholar

- Dissanayake, D.M.S.N., Mantilaka, M.M.M.G.P.G., Palihawadana, T.C., Chandrakumara, G.T.D., De Silva, R.T., Pitawala, H.M.T.G.A., de Silva, K.M., Amaratunga, G.A.J.: Facile and low-cost synthesis of pure hematite (α-Fe2O3) nanoparticles from naturally occurring laterites and their superior adsorption capability towards acid-dyes. RSC Adv. 9(37), 21249–21257 (2019). https://doi.org/10.1039/C9RA03756JArticleCASGoogle Scholar

- Barreca, D., Carraro, G., Gasparotto, A., Maccato, C.: 3-Metal oxide electrodes for photo-activated water splitting. In: Lin, Z., Ye, M., Wang, M.B.T.-M.P.M. Woodhead (eds.), Publishing in Materials, pp. 19–48. Woodhead Publishing (2018). https://doi.org/10.1016/B978-0-08-101977-1.00003-X

- Sivula, K.: Nanostructured α-Fe2O3 photoanodes. In: van de Kro, l R., Grätzel, M. (eds.), Photoelectrochemical Hydrogen Production. Electronic Materials: Science & Technology, pp. 121–156. Springer: Boston, MA (2012). https://doi.org/10.1007/978-1-4614-1380-6_4

- Mohapatra, M., Anand, S.: Synthesis and applications of nano-structured iron oxides/hydroxides—a review. Int. J. Eng. Sci. Technol. 2(8), 127–146 (2010) Google Scholar

- Bigham, J., Fitzpatrick, R., Schulze, D.: Iron Oxides. In: Dixon, J., Schulze, D. (eds.) Soil mineralogy with environmental applications, pp. 323–366. Soil Science Society of America, Madison (2002) Google Scholar

- Van Oosterhout, G.W., Rooijmans, C.J.M.: A new superstructure in gamma-ferric oxide. Nature, 44 (1958). https://doi.org/10.1038/181044a0

- Shmakov, A.N., Kryukova, G.N., Tsybulya, S.V., Chuvilin, A.L., Solovyeva, L.P.: Vacancy ordering in γ-Fe2O3: synchrotron X-ray powder diffraction and high-resolution electron microscopy studies. J. Appl. Crystallogr. 28(2), 141–145 (1995). https://doi.org/10.1107/S0021889894010113ArticleCASGoogle Scholar

- Tronc, E., Chanéac, C., Jolivet, J.P.: Structural and magnetic characterization of ε-Fe2O3. J. Solid State Chem. 139(1), 93–104 (1998). https://doi.org/10.1006/jssc.1998.7817ArticleCASGoogle Scholar

- García-Muñoz, J.L., Romaguera, A., Fauth, F., Nogués, J., Gich, M.: Unveiling a new high-temperature ordered magnetic phase in ϵ-Fe2O3. Chem. Mater. 29(22), 9705–9713 (2017). https://doi.org/10.1021/acs.chemmater.7b03417ArticleCASGoogle Scholar

- Balaev, D.A., Dubrovskiy, A.A., Yakushkin, S.S., Bukhtiyarova, G.A., Martyanov, O.N.: Temperature of the magnetic ordering of the trivalent iron oxide ε-Fe2O3. Phys. Solid State 61(3), 345–349 (2019). https://doi.org/10.1134/S1063783419030053ArticleCASGoogle Scholar

- Zboril, R., Mashlan, M., Petridis, D.: Iron (III) Oxides from thermal processes synthesis. Chem. Mater. 14(III), 969–982 (2002) Google Scholar

- Fleet, B.Y.M.E.: The structure of magnetite : two annealed natural magnetites, Fe3. 00504 and. Acta Crystallogr. 40x, 1491–1493 (1984) Google Scholar

- Hazen, R.M., Jeanloz, R.: Wüstite (Fe1-x O): a review of its defect structure and physical properties. Rev. Geophys. 22(1), 37–46 (1984). https://doi.org/10.1029/RG022i001p00037ArticleCASGoogle Scholar

- Finger, L.W., Hazen, R.M.: Crystal structure and isothermal compression of Fe2O3, Cr2O3, and V2O3 to 50 Kbars. J. Appl. Phys. 51(10), 5362–5367 (1980) ArticleCASGoogle Scholar

- Danno, T., Nakatsuka, D., Kusano, Y., Asaoka, H., Nakanishi, M., Fujii, T., Ikeda, Y., Takada, J.: Crystal structure of β-Fe2O3 and topotactic phase transformation to α-Fe2O3. Cryst. Growth Des. 13(2), 770–774 (2013) ArticleCASGoogle Scholar

- Gich, M., Frontera, C., Roig, A., Taboada, E., Molins, E., Rechenberg, H.R., Ardisson, J.D., Macedo, W.A.A., Ritter, C., Hardy, V., et al.: High- and low-temperature crystal and magnetic structures of ε-Fe2O3 and their correlation to its magnetic properties. Chem. Mater. 18(16), 3889–3897 (2006). https://doi.org/10.1021/cm060993lArticleCASGoogle Scholar

- Fleet, M.E.: The structure of magnetite: two annealed natural magnetites, Fe3.005O4 and Fe2.96Mg0.04O4. Acta Crystallogr. Sect. C 40(9), 1491–1493 (1984). https://doi.org/10.1107/S0108270184008489

- Fjellvåg, H., Grønvold, F., Stølen, S., Hauback, B.: On the crystallographic and magnetic structures of nearly stoichiometric iron monoxide. J. Solid State Chem. 124(1), 52–57 (1996) ArticleGoogle Scholar

- Prakasam, H.E., Varghese, O.K., Paulose, M., Mor, G.K., Grimes, C.A.: Synthesis and photoelectrochemical properties of nanoporous iron (III) oxide by potentiostatic anodization. Nanotechnology 17(17), 4285–4291 (2006). https://doi.org/10.1088/0957-4484/17/17/001ArticleCASGoogle Scholar

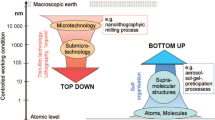

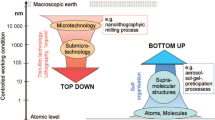

- Ganachari, S.V., Banapurmath, N.R., Salimath, B., Yaradoddi, J.S., Shettar, A.S., Hunashyal, A.M., Venkataraman, A., Patil, P., Shoba, H., Hiremath, G.B.: Synthesis techniques for preparation of nanomaterials. Handb. Ecomater. 1, 83–103 (2019). https://doi.org/10.1007/978-3-319-68255-6_149ArticleGoogle Scholar

- Zia, M., Phull, A.R., Ali, J.S.: Challenges of iron oxide nanoparticles. Nanotechnol. Sci. Appl. 9, 49–67 (2016) ArticleGoogle Scholar

- Ali, A., Zafar, H., Zia, M., Haq, I., Phull, A., Sarfraz Ali, J., Hussain, A.: Synthesis, Characterization, Applications, and Challenges of Iron Oxide Nanoparticles. Nanotechnol. Sci. Appl. 9, 49–67 (2016). https://doi.org/10.2147/NSA.S99986ArticleCASGoogle Scholar

- Tuček, J., Machala, L., Ono, S., Namai, A., Yoshikiyo, M., Imoto, K., Tokoro, H., Ohkoshi, S., Zbořil, R.: Zeta-Fe2O3—a new stable polymorph in iron (III) oxide family. Sci. Rep. 5(1), 15091 (2015). https://doi.org/10.1038/srep15091ArticleCASGoogle Scholar

- Lefèvre, G., Duc, M., Fédoroff, M.: Chapter 2—accuracy in the determination of acid-base properties of metal oxides surfaces. In: Lützenkirchen, J. B. T.-I. S (eds.), Surface Complexation Modelling, vol. 11, pp. 35–66. Elsevier (2006). https://doi.org/10.1016/S1573-4285(06)80046-3

- Colpas-Ruiz, M.A., Gnecco-Molina, C., Jiménez-Rodríguez, G.A., Pérez-Mendoza, J.A., Higuera-Cobos, Ó.F.: Synthesis of an anticorrosive pigment by thermal treatment of iron oxides from steel industry wastes. Rev. Fac. Ing. 28(52), 44–58 (2019) Google Scholar

- Hamed, M.H., Mueller, D.N., Müller, M.: Thermal phase design of ultrathin magnetic iron oxide films: from Fe3O4 to γ-Fe2O3 and FeO. J. Mater. Chem. C 8(4), 1335–1343 (2020). https://doi.org/10.1039/C9TC05921KArticleCASGoogle Scholar

- Perednis, D., Gauckler, L.J.: Thin film deposition using spray pyrolysis. J. Electroceramics 14(2), 103–111 (2005). https://doi.org/10.1007/s10832-005-0870-xArticleCASGoogle Scholar

- Marciello, M., Luengo, Y., Morales, M.P.: Iron oxide nanoparticles for cancer diagnosis and therapy. In: Nanoarchitectonics for Smart Delivery and Drug Targeting, pp. 667–694 (2016). https://doi.org/10.1016/B978-0-323-47347-7.00024-0

- Kastrinaki, G., Lorentzou, S., Karagiannakis, G., Rattenbury, M., Woodhead, J., Konstandopoulos, A.G.: Parametric synthesis study of iron based nanoparticles via aerosol spray pyrolysis route. J. Aerosol Sci. 115, 96–107 (2018). https://doi.org/10.1016/j.jaerosci.2017.10.005ArticleCASGoogle Scholar

- Duret, A., Grätzel, M.: Visible light-induced water oxidation on mesoscopic α-Fe2o3 films made by ultrasonic spray pyrolysis. J. Phys. Chem. B 109(36), 17184–17191 (2005). https://doi.org/10.1021/jp044127cArticleCASGoogle Scholar

- Popescu, V., Popescu, G.L., Indrea, E., Silipaş, D.T., Suciu, R.C.: Optical properties of Fe2O3 films obtained by spray pyrolysis. Proc. Int. Semicond. Conf. CAS 1, 109–112 (2010). https://doi.org/10.1109/SMICND.2010.5650236ArticleCASGoogle Scholar

- Ozcelik, B.K., Ergun, C.: Synthesis and characterization of iron oxide particles using spray pyrolysis technique. Ceram. Int. 41(2), 1994–2005 (2015). https://doi.org/10.1016/j.ceramint.2014.09.103ArticleCASGoogle Scholar

- Reddy, L.H., Arias, J.L., Nicolas, J., Couvreur, P.: Magnetic nanoparticles: design and characterization, toxicity and biocompatibility. Pharmaceut. Biomed. Appl. Chem. Rev. 112(11), 5818–5878 (2012). https://doi.org/10.1021/cr300068pArticleCASGoogle Scholar

- Wu, W., He, Q., Jiang, C.: Magnetic iron oxide nanoparticles: synthesis and surface functionalization strategies. Nanoscale Res. Lett. 3(11), 397–415 (2008). https://doi.org/10.1007/s11671-008-9174-9ArticleCASGoogle Scholar

- Ge, S., Shi, X., Sun, K., Li, C., Uher, C., Baker, J.R., Banaszak Holl, M.M., Orr, B.G.: Facile hydrothermal synthesis of iron oxide nanoparticles with tunable magnetic properties. J. Phys. Chem. C 113(31), 13593–13599 (2009). https://doi.org/10.1021/jp902953tArticleCASGoogle Scholar

- Chen, F., Gao, Q., Hong, G., Ni, J.: Synthesis and characterization of magnetite dodecahedron nanostructure by hydrothermal method. J. Magn. Magn. Mater. 320(11), 1775–1780 (2008). https://doi.org/10.1016/j.jmmm.2008.02.117ArticleCASGoogle Scholar

- Umar, A., Akhtar, M.S., Dar, G.N., Baskoutas, S.: Low-temperature synthesis of α-Fe2O3 hexagonal nanoparticles for environmental remediation and smart sensor applications. Talanta 116, 1060–1066 (2013). https://doi.org/10.1016/j.talanta.2013.08.026ArticleCASGoogle Scholar

- Teja, A.S., Koh, P.Y.: Synthesis, properties, and applications of magnetic iron oxide nanoparticles. Prog. Cryst. Growth Charact. Mater. 55(1–2), 22–45 (2009). https://doi.org/10.1016/j.pcrysgrow.2008.08.003ArticleCASGoogle Scholar

- Chang, H.S.W., Chiou, C.-C., Chen, Y.-W., Sheen, S.R.: Synthesis, characterization, and magnetic properties of Fe3O4 thin films prepared via a sol–gel method. J. Solid State Chem. 128(1), 87–92 (1997). https://doi.org/10.1006/jssc.1996.7159

- Cui, H., Liu, Y., Ren, W.: Structure switch between α-Fe2O3, γ-Fe2O3 and Fe3O4 during the large scale and low temperature sol-gel synthesis of nearly monodispersed iron oxide nanoparticles. Adv. Powder Technol. 24(1), 93–97 (2013). https://doi.org/10.1016/j.apt.2012.03.001ArticleCASGoogle Scholar

- Akbar, A., Imran, M., Riaz, S., Naseem, S.: Study of phase transition in iron oxide thin films. Mater. Today Proc. 2(10, Part B), 5405–5409 (2015). https://doi.org/10.1016/j.matpr.2015.11.059

- Kim, D.K., Mikhaylova, M., Zhang, Y., Muhammed, M.: Protective coating of superparamagnetic iron oxide nanoparticles. Chem. Mater. 15(8), 1617–1627 (2003). https://doi.org/10.1021/cm021349jArticleCASGoogle Scholar

- Babay, S., Mhiri, T., Toumi, M.: Synthesis, structural and spectroscopic characterizations of maghemite γ-Fe2O3 prepared by one-step coprecipitation route. J. Mol. Struct. 1085, 286–293 (2015). https://doi.org/10.1016/j.molstruc.2014.12.067ArticleCASGoogle Scholar

- Lee, S.J., Jeong, J.R., Shin, S.C., Kim, J.C., Kim, J.D.: Synthesis and characterization of superparamagnetic maghemite nanoparticles prepared by coprecipitation technique. J. Magn. Magn. Mater. 282(1–3), 147–150 (2004). https://doi.org/10.1016/j.jmmm.2004.04.035ArticleCASGoogle Scholar

- Farahmandjou, M., Soflaee, F.: Synthesis and characterization of α-Fe2O3 nanoparticles by simple co-precipitation method. Phys. Chem. Res. 3(3), 191–196 (2015). https://doi.org/10.22036/pcr.2015.9193

- Ferreira, M.G.S., Zheludkevich, M.L., Tedim, J., Yasakau, K.A.: Self-healing nanocoatings for corrosion control. In: Corrosion protection and control using nanomaterials, pp. 213–263. Elsevier (2012). https://doi.org/10.1533/9780857095800.2.213

- Rangaraju, R.R., Raja, K.S., Panday, A., Misra, M.: An Investigation on room temperature synthesis of vertically oriented arrays of iron oxide nanotubes by anodization of iron. Electrochim. Acta 55(3), 785–793 (2010). https://doi.org/10.1016/j.electacta.2009.07.012ArticleCASGoogle Scholar

- Xie, K., Guo, M., Huang, H., Liu, Y.: Fabrication of iron oxide nanotube arrays by electrochemical anodization. Corros. Sci. 88, 66–75 (2014). https://doi.org/10.1016/j.corsci.2014.07.019ArticleCASGoogle Scholar

- George, S.M.: Atomic layer deposition: an overview. Chem. Rev. 110(1), 111–131 (2010). https://doi.org/10.1021/cr900056bArticleCASGoogle Scholar

- Bachmann, J., Jing; Knez, M., Barth, S., Shen, H., Mathur, S., Gösele, U., Nielsch, K.: Ordered iron oxide nanotube arrays of controlled geometry and tunable magnetism by atomic layer deposition. J. Am. Chem. Soc. 129(31), 9554–9555 (2007).https://doi.org/10.1021/ja072465w

- Rooth, M., Johansson, A., Kukli, K., Aarik, J., Boman, M., Hårsta, A.: Atomic layer deposition of iron oxide thin films and nanotubes using ferrocene and oxygen as precursors. Chem. Vap. Depos. 14(3–4), 67–70 (2008). https://doi.org/10.1002/cvde.200706649ArticleCASGoogle Scholar

- Scheffe, J.R., Allendorf, M.D., Coker, E.N., Jacobs, B.W., McDaniel, A.H., Weimer, A.W.: Hydrogen production via chemical looping redox cycles using atomic layer deposition-synthesized iron oxide and cobalt ferrites. Chem. Mater. 23(8), 2030–2038 (2011). https://doi.org/10.1021/cm103622eArticleCASGoogle Scholar

- Yan, N., Qin, L., Hao, H., Hui, L., Zhao, F., Feng, H.: Iron oxide/aluminum/graphene energetic nanocomposites synthesized by atomic layer deposition: enhanced energy release and reduced electrostatic ignition hazard. Appl. Surf. Sci. 408, 51–59 (2017). https://doi.org/10.1016/j.apsusc.2017.02.169

- Rojac, T., Kosec, M., Malič, B., Holc, J.: The application of a milling map in the mechanochemical synthesis of ceramic oxides. J. Eur. Ceram. Soc. 26(16), 3711–3716 (2006). https://doi.org/10.1016/j.jeurceramsoc.2005.11.013

- Suryanarayana, C.: Mechanical alloying and milling. Prog. Mater. Sci. 46(1), 1–184 (2001). https://doi.org/10.1016/S0079-6425(99)00010-9

- Kwon, Y.-S., Gerasimov, K.B., Yoon, S.-K.: Ball temperatures during mechanical alloying in planetary mills. J. Alloys Compd. 346(1), 276–281 (2002). https://doi.org/10.1016/S0925-8388(02)00512-1

- Takacs, L., McHenry, J.S.: Temperature of the milling balls in shaker and planetary mills. J. Mater. Sci. 41(16), 5246–5249 (2006). https://doi.org/10.1007/s10853-006-0312-4ArticleCASGoogle Scholar

- Schmidt, R.; Scholze, H.; Stolle, A. Temperature Progression in a Mixer Ball Mill. Int. J. Ind. Chem.2016, 7. https://doi.org/https://doi.org/10.1007/s40090-016-0078-8.

- Lemine, O.M., Sajieddine, M., Bououdina, M., Msalam, R., Mufti, S., Alyamani, A.: Rietveld analysis and mössbauer spectroscopy studies of nanocrystalline hematite α-Fe2O3. J. Alloys Compd. 502(2), 279–282 (2010). https://doi.org/10.1016/j.jallcom.2010.04.175ArticleCASGoogle Scholar

- Arbain, R., Othman, M., Palaniandy, S.: Preparation of iron oxide nanoparticles by mechanical milling. Miner. Eng. 24(1), 1–9 (2011). https://doi.org/10.1016/j.mineng.2010.08.025ArticleCASGoogle Scholar

- Stanhaus, C., Alves, L.L.S., Ferrari, J.L., Padilha, J.C., Góes, M.S.; Hematite (α-Fe2O3) pure and doped with Eu 3+ obtained by high-energy ball milling process. Mater. Chem. Phys. 123385 (2020). https://doi.org/10.1016/j.matchemphys.2020.123385

- Zhao, Y., Wen, G.: Synthesis and magnetic properties of ε-Fe2O3 by ball milling and post annealing. J. Magn. Magn. Mater. 512, 167039 (2020). https://doi.org/10.1016/j.jmmm.2020.167039

- Cornell, R.M., Schwertmann, U.: The Iron Oxides (2007). https://doi.org/10.1002/9783527613229.ch01

- Hradil, D., Grygar, T., Hradilová, J., Bezdička, P.: Clay and iron oxide pigments in the history of painting. Appl. Clay Sci. 22(5), 223–236 (2003) ArticleCASGoogle Scholar

- Schwertmann, U.: Iron Oxides (2008). https://doi.org/10.1002/9783527613229.ch01

- Wu, H.B., Chen, J.S., Hng, H.H., Lou, X.W.: Nanostructured metal oxide-based materials as advanced anodes for lithium-ion batteries. Nanoscale 4(8), 2526–2542 (2012). https://doi.org/10.1039/c2nr11966h

- Liang, M., Zou, J., Zeng, X., Ding, W.: Nanostructured Fe2O3 based composites prepared through arc plasma method as anode materials in the lithium-ion battery. J. Nanomater. (2016).https://doi.org/10.1155/2016/1207907

- NuLi, Y., Zhang, P., Guo, Z., Liu, H.: Shape evolution of α-Fe2O3 and its size-dependent electrochemical properties for lithium-ion batteries. J. Electrochem. Soc. 155(3), A196 (2008). https://doi.org/10.1149/1.2826278ArticleCASGoogle Scholar

- Zeng, S., Tang, K., Li, T., Liang, Z., Wang, D., Wang, Y., Qi, Y., Zhou, W.: Facile route for the fabrication of porous hematite nanoflowers: its synthesis, growth mechanism, application in the lithium ion battery, and magnetic and photocatalytic properties. J. Phys. Chem. C 112(13), 4836–4843 (2008). https://doi.org/10.1021/jp0768773ArticleCASGoogle Scholar

- Pan, Q., Huang, K., Ni, S., Yang, F., Lin, S., He, D.: Synthesis of α-Fe2O3 dendrites by a hydrothermal approach and their application in lithium-ion batteries. J. Phys. D. Appl. Phys. 42(1), 1–6 (2009). https://doi.org/10.1088/0022-3727/42/1/015417ArticleCASGoogle Scholar

- Chen, J.S., Zhu, T., Yang, X.H., Yang, H.G., Lou, X.W.: Top-down fabrication of α-Fe2O3 single-crystal nanodiscs and microparticles. PDF 13162–13164 (2010) Google Scholar

- Wang, B., Chen, J.S., Wu, H.B., Wang, Z., Lou, X.W.: Quasiemulsion-templated formation of α-Fe2O3 hollow spheres with enhanced lithium storage properties. J. Am. Chem. Soc. 133(43), 17146–17148 (2011). https://doi.org/10.1021/ja208346s

- Wang, Z., Luan, D., Madhavi, S., Ming Li, C., Lou, X.W.: α-Fe2O3 nanotubes with superior lithium storage capability. Chem. Commun. 47(28), 8061–8063 (2011). https://doi.org/10.1039/c1cc12111aArticleCASGoogle Scholar

- Xu, L., Tian, Y., Liu, T., Li, H., Qiu, J., Li, S., Li, H., Yuan, S., Zhang, S.: α-Fe2O3 nanoplates with superior electrochemical performance for lithium-ion batteries. Green Energy Environ. 3(2), 156–162 (2018). https://doi.org/10.1016/j.gee.2018.01.005ArticleGoogle Scholar

- Lv, X., Deng, J., Wang, B., Zhong, J., Sham, T.K., Sun, X., Sun, X.: γ-Fe2O3@CNTs anode materials for lithium ion batteries investigated by electron energy loss spectroscopy. Chem. Mater. 29(8), 3499–3506 (2017). https://doi.org/10.1021/acs.chemmater.6b05356ArticleCASGoogle Scholar

- Poizot, P., Dolhem, F., Environ, E., Poizot, P., Dolhem, F.: Clean energy new deal for a sustainable world: from non-CO2 generating energy sources to greener electrochemical storage devices. Energy Environ. Sci. 4(6), 2003–2019 (2011). https://doi.org/10.1039/c0ee00731eArticleCASGoogle Scholar

- Walter, M.G., Warren, E.L., McKone, J.R., Boettcher, S.W., Mi, Q., Santori, E.A., Lewis, N.S.: Solar water splitting cells. Chem. Rev. 110(11), 6446–6473 (2010). https://doi.org/10.1021/cr1002326ArticleCASGoogle Scholar

- Kannan, N., Vakeesan, D.: Solar energy for future world: a review. Renew. Sustain. Energy Rev. 62, 1092–1105 (2016). https://doi.org/10.1016/j.rser.2016.05.022ArticleGoogle Scholar

- Bard, A.J., Fox, M.A.: Artificial photosynthesis: solar splitting of water to hydrogen and oxygen. Acc. Chem. Res. 28(3), 141–145 (1995). https://doi.org/10.1021/ar00051a007ArticleCASGoogle Scholar

- Tachibana, Y., Vayssieres, L., Durrant, J.R.: Artificial photosynthesis for solar water-splitting. Nat. Photon. 6(8), 511–518 (2012). https://doi.org/10.1038/nphoton.2012.175ArticleCASGoogle Scholar

- Van de Krol, R., Grätzel, M.: Photoelectrochemical Hydrogen Production. In: Electronic Materials: Science & Technology, 1st ed., vol. 102 Springer US, Boston, MA (2012). https://doi.org/10.1007/978-1-4614-1380-6

- Cho, S., Jang, J.-W.W., Lee, K.-H.H., Lee, J.S.: Research update: strategies for efficient photoelectrochemical water splitting using metal oxide photoanodes. APL Mater. 2(1), 10703 (2014). https://doi.org/10.1063/1.4861798ArticleCASGoogle Scholar

- Chang, W.J., Lee, K.-H., Ha, J.-I., Nam, K.T.: Hydrogen production via water electrolysis: the benefits of a solar cell-powered process. IEEE Electrif. Mag. 6(1), 19–25 (2018). https://doi.org/10.1109/MELE.2017.2784632ArticleGoogle Scholar

- Goto, Y., Hisatomi, T., Wang, Q., Higashi, T., Ishikiriyama, K., Maeda, T., Sakata, Y., Okunaka, S., Tokudome, H., Katayama, M., et al.: A Particulate photocatalyst water-splitting panel for large-scale solar hydrogen generation. Joule 2(3), 509–520 (2018). https://doi.org/10.1016/j.joule.2017.12.009ArticleCASGoogle Scholar

- Kim, J.H., Hansora, D., Sharma, P., Jang, J.-W., Lee, J.S.: Toward practical solar hydrogen production—an artificial photosynthetic leaf-to-farm challenge. Chem. Soc. Rev. 48(7), 1908–1971 (2019). https://doi.org/10.1039/C8CS00699GArticleCASGoogle Scholar

- Pan, Z., Röhr, J.A., Ye, Z., Fishman, Z.S., Zhu, Q., Shen, X., Hu, S.: Elucidating charge separation in particulate photocatalysts using nearly intrinsic semiconductors with small asymmetric band bending. Sustain. Energy Fuels 3(3), 850–864 (2019). https://doi.org/10.1039/C9SE00036DArticleCASGoogle Scholar

- Qi, J., Zhang, W., Cao, R.: Solar-to-hydrogen energy conversion based on water splitting. Adv. Energy Mater. 8(5), 1701620 (2018). https://doi.org/10.1002/aenm.201701620ArticleCASGoogle Scholar

- Xiao, J., Huang, H., Huang, Q., Li, X., Hou, X., Zhao, L., Ma, R., Chen, H., Li, Y.: Remarkable improvement of the turn–on characteristics of a Fe2O3 photoanode for photoelectrochemical water splitting with coating a fecow oxy-hydroxide gel. Appl. Catal. B Environ. 212, 89–96 (2017). https://doi.org/10.1016/j.apcatb.2017.04.075ArticleCASGoogle Scholar

- Bolton, J.R., Strickler, S.J., Connolly, J.S.: Limiting and realizable efficiencies of solar photolysis of water. Nature 316(6028), 495–500 (1985). https://doi.org/10.1038/316495a0ArticleCASGoogle Scholar

- Turner, J.A.: A realizable renewable energy future. Science 80, 285 (5428), 687–689 (1999). https://doi.org/10.1126/science.285.5428.687

- Maabong, K., Machatine, A.G.J., Mwankemwa, B.S., Braun, A., Bora, D.K., Toth, R., Diale, M.: Nanostructured hematite thin films for photoelectrochemical water splitting. Phys. B Condens. Matter 535, 67–71 (2018). https://doi.org/10.1016/j.physb.2017.06.054ArticleCASGoogle Scholar

- Townsend, T.K., Sabio, E.M., Browning, N.D., Osterloh, F.E.: Photocatalytic water oxidation with suspended alpha-Fe2O3 particles-effects of nanoscaling. Energy Environ. Sci. 4(10), 4270 (2011). https://doi.org/10.1039/c1ee02110aArticleCASGoogle Scholar

- Zhang, M., Lin, Y., Mullen, T.J., Lin, W.-F., Sun, L.-D., Yan, C.-H., Patten, T.E., Wang, D., Liu, G.: Improving Hematite’s solar water splitting efficiency by incorporating rare-earth upconversion nanomaterials. J. Phys. Chem. Lett. 3(21), 3188–3192 (2012). https://doi.org/10.1021/jz301444aArticleCASGoogle Scholar

- Fujishima, A., Honda, K.: Electrochemical photolysis of water at a semiconductor electrode. Nature 238(5358), 37–38 (1972). https://doi.org/10.1038/238037a0ArticleCASGoogle Scholar

- Wang, J.-J.J., Hu, Y., Toth, R., Fortunato, G., Braun, A.: A facile nonpolar organic solution process of a nanostructured hematite photoanode with high efficiency and stability for water splitting. J. Mater. Chem. A 4(8), 2821–2825 (2016). https://doi.org/10.1039/C5TA06439BArticleCASGoogle Scholar

- De Carvalho, V.A.N., Luz, R.A.D.S., Lima, B.H., Crespilho, F.N., Leite, E.R., Souza, F.L.: Highly oriented hematite nanorods arrays for photoelectrochemical water splitting. J. Power Sources 205, 525–529 (2012). https://doi.org/10.1016/j.jpowsour.2012.01.093ArticleCASGoogle Scholar

- Kim, J.Y., Magesh, G., Youn, D.H., Jang, J.-W.W., Kubota, J., Domen, K., Lee, J.S.: Single-crystalline, wormlike hematite photoanodes for efficient solar water splitting. Sci. Rep. 3(1), 2681 (2013). https://doi.org/10.1038/srep02681ArticleGoogle Scholar

- Kalita, E., Baruah, J.: Environmental Remediation. Elsevier Inc. (2020). https://doi.org/10.1016/b978-0-12-813357-6.00014-0

- Yeung, A.T.: Remediation technologies for contaminated sites. Adv. Environ. Geotech. 328–369 (2010). https://doi.org/10.1007/978-3-642-04460-1_25

- Zhu, J., Wei, S., Chen, M., Gu, H., Rapole, S.B., Pallavkar, S., Ho, T.C., Hopper, J., Guo, Z.: Magnetic nanocomposites for environmental remediation. Adv. Powder Technol. 24(2), 459–467 (2013). https://doi.org/10.1016/j.apt.2012.10.012ArticleCASGoogle Scholar

- Oller, I., Malato, S., Sánchez-Pérez, J.A.: Combination of advanced oxidation processes and biological treatments for wastewater decontamination-a review. Sci. Total Environ. 409(20), 4141–4166 (2011). https://doi.org/10.1016/j.scitotenv.2010.08.061ArticleCASGoogle Scholar

- Xu, P., Zeng, G.M., Huang, D.L., Feng, C.L., Hu, S., Zhao, M.H., Lai, C., Wei, Z., Huang, C., Xie, G.X., et al.: Use of iron oxide nanomaterials in wastewater treatment: a review. Sci. Total Environ. 424, 1–10 (2012) ArticleCASGoogle Scholar

- Hao, Y.M., Man, C., Hu, Z.B.: Effective removal of Cu (II) ions from aqueous solution by amino-functionalized magnetic nanoparticles. J. Hazard. Mater. 184(1–3), 392–399 (2010). https://doi.org/10.1016/j.jhazmat.2010.08.048ArticleCASGoogle Scholar

- Hu, H., Wang, Z., Pan, L.: Synthesis of monodisperse Fe3O4@silica core-shell microspheres and their application for removal of heavy metal ions from water. J. Alloys Compd. 492(1–2), 656–661 (2010). https://doi.org/10.1016/j.jallcom.2009.11.204ArticleCASGoogle Scholar

- Dave, P.N., Chopda, L.V.: Application of iron oxide nanomaterials for the removal of heavy metals. J. Nanotechnol. (2014). https://doi.org/10.1155/2014/398569

- Zhang, S., Niu, H., Hu, Z., Cai, Y., Shi, Y.: Preparation of carbon coated Fe3O4 nanoparticles and their application for solid-phase extraction of polycyclic aromatic hydrocarbons from environmental water samples. J. Chromatogr. A 1217(29), 4757–4764 (2010). https://doi.org/10.1016/j.chroma.2010.05.035ArticleCASGoogle Scholar

- Abdel-Shafy, H.I., Mansour, M.S.M.: A review on polycyclic aromatic hydrocarbons: source, environmental impact, effect on human health and remediation. Egypt. J. Pet. 25(1), 107–123 (2016). https://doi.org/10.1016/j.ejpe.2015.03.011ArticleGoogle Scholar

- Zhang, W-X.: Nanoscale iron particles for environmental remediation: an overview. J. Nanoparticle Res. 5(3–4), 323–332 (2003) Google Scholar

- Das, D., Sureshkumar, M.K., Koley, S., Mithal, N., Pillai, C.G.S.: Sorption of uranium on magnetite nanoparticles. J. Radioanal. Nucl. Chem. 285(3), 447–454 (2010). https://doi.org/10.1007/s10967-010-0627-0ArticleCASGoogle Scholar

- Li, Y., Zhao, H., Ban, H., Yang, M.: Composites of Fe2O3 nanosheets with polyaniline : preparation, gas sensing properties and sensing mechanism. Sensors Actuators B. Chem. (2017). https://doi.org/10.1016/j.snb.2017.01.103ArticleGoogle Scholar

- Dussán, K.J., Giese, E.C., Vieira, G.N.A., Lima, L.N., Silva, D.D.V.: Pharmaceutical and biomedical applications of magnetic iron-oxide nanoparticles. In: Metal Nanoparticles in Pharma, pp. 77–99. Springer (2017) Google Scholar

- Nikiforov, V., Filinova, E.: Biomedical applications of magnetic nanoparticles. In: Magnetic Nanoparticles, pp. 393–455 (2009). https://doi.org/10.1002/9783527627561.ch10

- Chang, D., Lim, M., Goos, J.A.C.M., Qiao, R., Ng, Y.Y., Mansfeld, F.M., Jackson, M., Davis, T.P., Kavallaris, M.: Biologically targeted magnetic hyperthermia: potential and limitations. Front. Pharmacol. 9(AUG) (2018). https://doi.org/10.3389/fphar.2018.00831

- Morber, J.R.: 1D nanowires : understanding growth and properties as steps toward biomedical and electrical application. Growth (Lakeland) (2008) Google Scholar

- Berger, A.: How does it work? magnetic resonance imaging. BMJ 324(7328), 35 (2002). https://doi.org/10.1136/bmj.324.7328.35ArticleGoogle Scholar

- Patravale, V., Joshi, M.: Nanocarriers for imaging applications. In: Fanun, M. (ed.) Colloids in Drug Delivery, pp. 563–611. CRC Press, Boca Raton, Florida, US (2010) ChapterGoogle Scholar

- Weissleder, R., Moore, A., Mahmood, U., Bhorade, R., Benveniste, H., Chiocca, E.A., Basilion, J.P.: In vivo magnetic resonance imaging of transgene expression. Nat. Med. 6(3), 351–354 (2000). https://doi.org/10.1038/73219ArticleCASGoogle Scholar

- Hinds, K.A., Hill, J.M., Shapiro, E.M., Laukkanen, M.O., Silva, A.C., Combs, C.A., Varney, T.R., Balaban, R.S., Koretsky, A.P., Dunbar, C.E.: Highly efficient endosomal labeling of progenitor and stem cells with large magnetic particles allows magnetic resonance imaging of single cells. Blood 102(3), 867–872 (2003). https://doi.org/10.1182/blood-2002-12-3669ArticleCASGoogle Scholar

- Lok, C.: Picture perfect. Nature 412(6845), 372–374 (2001). https://doi.org/10.1038/35086702ArticleCASGoogle Scholar

- Marghussian, V.: Nano-Glass Ceramics. Elsevier (2015). https://doi.org/10.1016/C2014-0-01294-4

- Arami, H., Khandhar, A., Liggitt, D., Krishnan, K.M.: In vivo delivery, pharmacokinetics, biodistribution and toxicity of iron oxide nanoparticles. Chem. Soc. Rev. 44(23), 8576–8607 (2015). https://doi.org/10.1039/C5CS00541HArticleCASGoogle Scholar

- Berry, C.C., Curtis, A.S.G.: Functionalisation of magnetic nanoparticles for applications in biomedicine. J. Phys. D. Appl. Phys. 36(13), R198–R206 (2003). https://doi.org/10.1088/0022-3727/36/13/203ArticleCASGoogle Scholar

- Pultrum, B.B., van der Jagt, E.J., van Westreenen, H.L., van Dullemen, H.M., Kappert, P., Groen, H., Sietsma, J., Oudkerk, M., Plukker, J.T.M., van Dam, G.M.: Detection of lymph node metastases with ultrasmall super paramagnetic iron oxide (USPIO)-enhanced magnetic resonance imaging in oesophageal cancer: a feasibility study. Cancer Imaging 9(1), 19–28 (2009). https://doi.org/10.1102/1470-7330.2009.0004ArticleCASGoogle Scholar

- Qin, Y., Zhuo, L., Cai, J., He, X., Liu, B., Feng, C., Zhang, L.: In vivo monitoring of magnetically labeled mesenchymal stem cells homing to rabbit hepatic VX2 tumors using magnetic resonance imaging. Mol. Med. Rep. 17(1), 452–458 (2018). https://doi.org/10.3892/mmr.2017.7902ArticleCASGoogle Scholar

- Philips, B.W.J., Stijns, R.C.H., Rietsch, S.H.G., Brunheim, S., Barentsz, J.O., Fortuin, A.S., Quick, H.H., Orzada, S., Maas, M.C., Scheenen, T.W.J.: USPIO-enhanced MRI of pelvic lymph nodes at 7-T: preliminary experience. Eur. Radiol. 29(12), 6529–6538 (2019). https://doi.org/10.1007/s00330-019-06277-7ArticleGoogle Scholar

- Semple, S., Alam, S.R., MacGillivray, T.J., Dweck, M.R., Shah, A.S., Richards, J., Wang, C., Lang, N., McKillop, G., Mirsadraee, S., et al.: Quantitative myocardial inflammation assessed using a novel USPIO-magnetic resonance imaging acquisition and analysis protocol. J. Cardiovasc. Magn. Reson. 15(S1), O114 (2013). https://doi.org/10.1186/1532-429x-15-s1-o114ArticleGoogle Scholar

- Gkagkanasiou, M., Ploussi, A., Gazouli, M., Efstathopoulos, E.P.: USPIO-enhanced MRI neuroimaging: a review. J. Neuroimag. 26(2), 161–168 (2016). https://doi.org/10.1111/jon.12318ArticleGoogle Scholar

- Lagan, J., Naish, J.H., Simpson, K., Zi, M., Cartwright, E.J., Foden, P., Morris, J., Clark, D., Birchall, L., Caldwell, J., et al.: Substrate for the myocardial inflammation–heart failure hypothesis identified using novel USPIO methodology. JACC Cardiovasc. Imag. 1–11 (2020). https://doi.org/10.1016/j.jcmg.2020.02.001

- Moding, E.J., Kastan, M.B., Kirsch, D.G.: Strategies for optimizing the response of cancer and normal tissues to radiation. Nat. Rev. Drug Discov. 12(7), 526–542 (2013). https://doi.org/10.1038/nrd4003ArticleCASGoogle Scholar

- Wust, P., Hildebrandt, B., Sreenivasa, G., Rau, B., Gellermann, J., Riess, H., Felix, R., Schlag, P.: Hyperthermia in combined treatment of cancer. Lancet Oncol. 3(8), 487–497 (2002). https://doi.org/10.1016/S1470-2045(02)00818-5ArticleCASGoogle Scholar

- Jordan, A., Wust, P., Scholz, R., Tesche, B., Fähling, H., Mitrovics, T., Vogl, T., Cervós-Navarro, J., Felix, R.: Cellular uptake of magnetic fluid particles and their effects on human adenocarcinoma cells exposed to AC magnetic fields in vitro. Int. J. Hyperth. 12(6), 705–722 (1996). https://doi.org/10.3109/02656739609027678ArticleCASGoogle Scholar

- Nielsen, O.S., Horsman, M., Overgaard, J.: A future for hyperthermia in cancer treatment? Eur. J. Cancer 37(13), 1587–1589 (2001). https://doi.org/10.1016/S0959-8049(01)00193-9ArticleCASGoogle Scholar

- Gilchrist, R.K., Medal, R., Shorey, W.D., Hanselman, R.C., Parrott, J.C., Taylor, C.B.: Selective inductive heating of lymph nodes. Ann. Surg. 146(4), 596–606 (1957). https://doi.org/10.1097/00000658-195710000-00007ArticleCASGoogle Scholar

- Jordan, A., Scholz, R., Wust, P., Fähling, H., Felix, R.: Magnetic fluid hyperthermia (MFH): cancer treatment with AC magnetic field induced excitation of biocompatible superparamagnetic nanoparticles. J. Magn. Magn. Mater. 201(1–3), 413–419 (1999). https://doi.org/10.1016/S0304-8853(99)00088-8ArticleCASGoogle Scholar

- Hergt, R., Andrä, W.: Magnetic hyperthermia and thermoablation. In: Andrä, W., Nowak, H. (eds.) Magnetism in Medicine, pp. 550–570. WILEY-VCH Verlag GmbH & Co., Weinheim, Germany (2007) Google Scholar

- Chudasama, B., Vala, A.K., Andhariya, N., Upadhyay, R.V., Mehta, R.V.: Enhanced antibacterial activity of bifunctional Fe3O4-Ag core-shell nanostructures. Nano Res. 2(12), 955–965 (2009). https://doi.org/10.1007/s12274-009-9098-4ArticleCASGoogle Scholar

- Tran, N., Mir, A., Mallik, D., Sinha, A., Nayar, S., Webster, T.J.: Bactericidal effect of iron oxide nanoparticles on staphylococcus aureus. Int. J. Nanomed. 5(1), 277–283 (2010). https://doi.org/10.2147/ijn.s9220ArticleCASGoogle Scholar

- Hajipour, M.J., Fromm, K.M., Akbar Ashkarran, A., Jimenez de Aberasturi, D., de Larramendi, I.R., Rojo, T., Serpooshan, V., Parak, W.J., Mahmoudi, M.: Antibacterial properties of nanoparticles. Trends Biotechnol. 30(10), 499–511 (2012). https://doi.org/10.1016/j.tibtech.2012.06.004

- Sau, T.K., Biswas, A., Ray, P.: Metal nanoparticles in nanomedicine: advantages and scope. Metal Nanopart. 121–168 (2018). https://doi.org/10.1002/9783527807093.ch6

- Majidi, S., Zeinali Sehrig, F., Samiei, M., Milani, M., Abbasi, E., Dadashzadeh, K., Akbarzadeh, A.: Magnetic nanoparticles: applications in gene delivery and gene therapy. Artif. Cells, Nanomedicine Biotechnol. 44(4), 1186–1193 (2016). https://doi.org/10.3109/21691401.2015.1014093

- Dinali, R., Ebrahiminezhad, A., Manley-Harris, M., Ghasemi, Y., Berenjian, A.: Iron oxide nanoparticles in modern microbiology and biotechnology. Crit. Rev. Microbiol. 43(4), 493–507 (2017). https://doi.org/10.1080/1040841X.2016.1267708ArticleCASGoogle Scholar

- Dagan, R., Barkai, G., Givon-Lavi, N., Sharf, A.Z., Vardy, D., Cohen, T., Lipsitch, M., Greenberg, D.: Seasonality of antibiotic-resistant streptococcus pneumoniae that causes acute otitis media: a clue for an antibiotic-restriction policy? J. Infect. Dis. 197(8), 1094–1102 (2008). https://doi.org/10.1086/528995ArticleGoogle Scholar

- Laurent, S., Saei, A.A., Behzadi, S., Panahifar, A., Mahmoudi, M.: Superparamagnetic iron oxide nanoparticles for delivery of therapeutic agents: opportunities and challenges. Expert Opin. Drug Deliv. 11(9), 1449–1470 (2014). https://doi.org/10.1517/17425247.2014.924501ArticleCASGoogle Scholar

- Vangijzegem, T., Stanicki, D., Laurent, S.: Magnetic iron oxide nanoparticles for drug delivery: applications and characteristics. Expert Opin. Drug Deliv. 16(1), 69–78 (2019). https://doi.org/10.1080/17425247.2019.1554647ArticleCASGoogle Scholar

- Hola, K., Markova, Z., Zoppellaro, G., Tucek, J., Zboril, R.: Tailored functionalization of iron oxide nanoparticles for MRI, drug delivery, magnetic separation and immobilization of biosubstances. Biotechnol. Adv. 33(6), 1162–1176 (2015). https://doi.org/10.1016/j.biotechadv.2015.02.003ArticleCASGoogle Scholar

- Wei, W., Xu, C., Wu, H.: Magnetic iron oxide nanoparticles mediated gene therapy for breast cancer—an in vitro study. J. Huazhong Univ. Sci. Technol. 26(6), 728–730 (2006). https://doi.org/10.1007/s11596-006-0628-yArticleCASGoogle Scholar

- Dowaidar, M., Abdelhamid, H.N., Hällbrink, M., Freimann, K., Kurrikoff, K., Zou, X., Langel, Ü.: Magnetic nanoparticle assisted self-assembly of cell penetrating peptides-oligonucleotides complexes for gene delivery. Sci. Rep. 7(1) (2017). https://doi.org/10.1038/s41598-017-09803-z

- Kami, D., Takeda, S., Itakura, Y., Gojo, S., Watanabe, M., Toyoda, M.: Application of magnetic nanoparticles to gene delivery. Int. J. Mol. Sci. 12(6), 3705–3722 (2011). https://doi.org/10.3390/ijms12063705ArticleCASGoogle Scholar

- Ayers, J.W., Stephens, R.A.: Gamma Ferric Oxide for Magnetic Impulse Record Members (1962) Google Scholar

- Coccia, M.: General sources of general purpose technologies in complex societies: theory of global leadership-driven innovation. Warfare Human Devel. Technol. Soc. 2015(42), 199–226 (2014). https://doi.org/10.1016/j.techsoc.2015.05.008ArticleGoogle Scholar

- Mederos-Henry, F., Mahin, J., Pichon, B.P., Dîrtu, M.M., Garcia, Y., Delcorte, A., Bailly, C., Huynen, I., Hermans, S.: Highly efficient wideband microwave absorbers based on zero-valent Fe@γ-Fe2O3 and Fe/Co/Ni carbon-protected alloy nanoparticles supported on reduced graphene oxide. Nanomaterials 9(9) (2019). https://doi.org/10.3390/nano9091196

- Kong, L.B., Liu, L., Yang, Z., Li, S., Zhang, T.: Magnetic nanomaterials for electromagnetic wave absorption. Magn. Nanomater. Fundam. Synth. Appl. 473–514 (2017). https://doi.org/10.1002/9783527803255.ch15

- Ni, S., Lin, S., Pan, Q., Yang, F., Huang, K., He, D.: Hydrothermal synthesis and microwave absorption properties of Fe3O4 nanocrystals. J. Phys. D. Appl. Phys. 42(5) (2009). https://doi.org/10.1088/0022-3727/42/5/055004

- Ni, S., Sun, X., Wang, X., Zhou, G., Yang, F., Wang, J., He, D.: Low temperature synthesis of Fe3O4 micro-spheres and its microwave absorption properties. Mater. Chem. Phys. 124(1), 353–358 (2010). https://doi.org/10.1016/j.matchemphys.2010.06.046ArticleCASGoogle Scholar

- Yan, A., Liu, Y., Liu, Y., Li, X., Lei, Z., Liu, P.: A NaAc-assisted large-scale coprecipitation synthesis and microwave absorption efficiency of Fe3O4 nanowires. Mater. Lett. 68, 402–405 (2012). https://doi.org/10.1016/j.matlet.2011.10.093ArticleCASGoogle Scholar

- Liu, Y., Zhao, K., Drew, M.G.B., Liu, Y.A.: Theoretical and practical clarification on the calculation of reflection loss for microwave absorbing materials. AIP Adv. 8(1) (2018). https://doi.org/10.1063/1.4991448

- Liu, Y., Drew, M.G.B., Li, H., Liu, Y.: An experimental and theoretical investigation into methods concerned with “reflection loss” for microwave absorbing materials. Mater. Chem. Phys.243 (2020). https://doi.org/10.1016/j.matchemphys.2020.122624

- George, J.M., Antony, A., Mathew, B.: Metal oxide nanoparticles in electrochemical sensing and biosensing: a review. Microchim. Acta 185(7), 358 (2018). https://doi.org/10.1007/s00604-018-2894-3ArticleCASGoogle Scholar

- Chauhan, N., Pundir, C.S.: An amperometric biosensor based on acetylcholinesterase immobilized onto iron oxide nanoparticles/multi-walled carbon nanotubes modified gold electrode for measurement of organophosphorus insecticides. Anal. Chim. Acta 701(1), 66–74 (2011). https://doi.org/10.1016/j.aca.2011.06.014ArticleCASGoogle Scholar

- Lee, S., Oh, J., Kim, D., Piao, Y.: A sensitive electrochemical sensor using an iron oxide/graphene composite for the simultaneous detection of heavy metal ions. Talanta 160, 528–536 (2016). https://doi.org/10.1016/j.talanta.2016.07.034ArticleCASGoogle Scholar

- Zhang, Y., Cheng, Y., Zhou, Y., Li, B., Gu, W., Shi, X., Xian, Y.: Electrochemical sensor for bisphenol a based on magnetic nanoparticles decorated reduced graphene oxide. Talanta 107, 211–218 (2013). https://doi.org/10.1016/j.talanta.2013.01.012ArticleCASGoogle Scholar

- Hosford, W.F.: Iron and Steel. Cambridge University Press, Cambridge (2012). https://doi.org/10.1017/CBO9781139086233

- Seifan, M., Samani, A.K., Berenjian, A.: Induced calcium carbonate precipitation using bacillus species. Appl. Microbiol. Biotechnol. 100(23), 9895–9906 (2016). https://doi.org/10.1007/s00253-016-7701-7ArticleCASGoogle Scholar

- Seifan, M., Sarmah, A.K., Samani, A.K., Ebrahiminezhad, A., Ghasemi, Y., Berenjian, A.: Mechanical properties of bio self-healing concrete containing immobilized bacteria with iron oxide nanoparticles. Appl. Microbiol. Biotechnol. 102(10), 4489–4498 (2018). https://doi.org/10.1007/s00253-018-8913-9ArticleCASGoogle Scholar

- Li, H., Gang Xiao, H., Ping Ou, J.: A study on mechanical and pressure-sensitive properties of cement mortar with nanophase materials. Cem. Concr. Res. 34(3), 435–438 (2004). https://doi.org/10.1016/j.cemconres.2003.08.025

- Kourkoutas, Y., Bekatorou, A., Banat, I.M., Marchant, R., Koutinas, A.A.: Immobilization technologies and support materials suitable in alcohol beverages production: a review. Food Microbiol. 21(4), 377–397 (2004). https://doi.org/10.1016/j.fm.2003.10.005ArticleCASGoogle Scholar

- Royal, H.: Polishing compound residues in gold jewellery alloys. Gold Bull. 22(2), 42–47 (1989). https://doi.org/10.1007/BF03214706ArticleCASGoogle Scholar

- Marcot, G.C., Cauwenberg, W.J., Lamanna, S.: A. Production of Iron Oxide Pigments. Google Patents (1951) Google Scholar

- Ansari, F., Grigoriev, P., Libor, S., Tothill, I.E., Ramsden, J.J.: DBT degradation enhancement by decorating rhodococcus erythropolis IGST8 with magnetic Fe3O4 nanoparticles. Biotechnol. Bioeng. 102(5), 1505–1512 (2009). https://doi.org/10.1002/bit.22161ArticleCASGoogle Scholar

- Akay, G., Erhan, E., Keskinler, B.: Bioprocess intensification inflow-through monolithic microbioreactors with immobilized bacteria. Biotechnol. Bioeng. 90(2), 180–190 (2005). https://doi.org/10.1002/bit.20376ArticleCASGoogle Scholar

Acknowledgements

The authors are gratefully acknowledges Fundação Araucária, CONICET and UNILA/Pró-Reitoria de Pesquisa e Pós-graduação (PRPPG) for financial support. Also, to B.Sc. Sandy Gonzalez Hernandez (UNILA) for his contributions and support while writing this chapter.